“chitubox what is infill structure for hollowing 3d prints” I’ve been exploring how to make hollow prints light and strong. ChituBox slicer software is key to this. It lets me fine-tune the infill structure, which has changed the game for me. In this article, I’ll show you how to master hollow prints with ChituBox.

Resin 3D printing has changed the game for quick prototypes and small-scale making. It’s super precise and detailed. But, it can be pricey and slow for big models. That’s where hollowing comes in, and ChituBox helps you get amazing results.

Getting good at infill structure in ChituBox is essential for making hollow prints that are both light and strong. By tweaking these settings, you can save resin, print faster, and make prints more durable. We’ll explore ChituBox’s hollowing features in detail. This will help you improve your 3D printing skills.

Introduction to ChituBox Hollowing Features

Resin 3D printing can make hollow models, which have big advantages. ChituBox, a top slicing software, offers tools to make your prints better and use less material. We’ll look at how hollowing works, its benefits, and ChituBox’s tools for great hollow prints.

Basic Concepts of Model Hollowing

Model hollowing makes a 3D model hollow, saving material. It’s great for big models, as it cuts down resin use and print time. Hollow models are light but still strong.

Benefits of Hollow Prints in Resin 3D Printing

- Material Savings: Hollow prints need less resin, saving money and reducing waste.

- Faster Print Times: Less material means quicker prints.

- Improved Curing: Hollow models cure better, as resin travels less.

ChituBox Software Overview

ChituBox is a top slicing software for resin 3D printers. It has tools for making hollow prints. You can adjust wall thickness, infill density, and support structures for quality prints. ChituBox makes adding hollow prints easy.

Essential Settings for Successful Hollow Prints

To get great hollow prints in ChituBox, you need to pay close attention to a few key settings. These include wall thickness, infill density, and where to put support structures. The best settings will change based on your model’s size and how complex it is. So, it’s important to try different settings for each project.

Keeping the right wall thickness is very important. Thinner walls use less material and print faster, but they might not be as strong. On the other hand, walls that are too thick use more resin and take longer to print. For the best look, aim for a layer height of about 0.02mm. Some top printers can even do layers as small as 0.01mm or 0.005mm.

Changing the infill density is also key. More infill makes your model stronger but takes longer to print and uses more material. Finding the right balance is crucial. Hollow models need enough inside structure to keep their shape but shouldn’t be too dense.

How you orient your model and where you place support structures matters a lot too. ChituBox’s auto-orientation feature can help you find the best way to print. This can reduce the need for supports and make your prints look better.

By carefully thinking about these important settings, you can make the most of ChituBox’s hollowing features. This way, you can create high-quality, efficient hollow prints that fit your project’s needs.

Understanding Wall Thickness Parameters

Wall thickness is key for hollow 3D prints to be stable and strong. In ChituBox, you can adjust wall thickness to improve print quality and save material. This is important for making your prints strong and efficient.

Minimum Wall Thickness Requirements

The minimum wall thickness needed depends on the resin and model size. Generally, aim for 1-2 millimeters to keep prints stable. This can change based on resin type and design complexity.

Optimizing Shell Strength

Thicker walls make prints stronger but use more material. This can raise costs. In ChituBox, try different wall thicknesses to find the right balance. Adjusting thickness for different parts of your model can also help.

Impact on Print Stability

Wall thickness greatly affects print stability, especially in tall or complex designs. Thicker walls help prevent warping and cracking. ChituBox lets you adjust wall thickness for different parts of your model. This helps improve stability and success rates.

chitubox what is infill structure for hollowing 3d prints

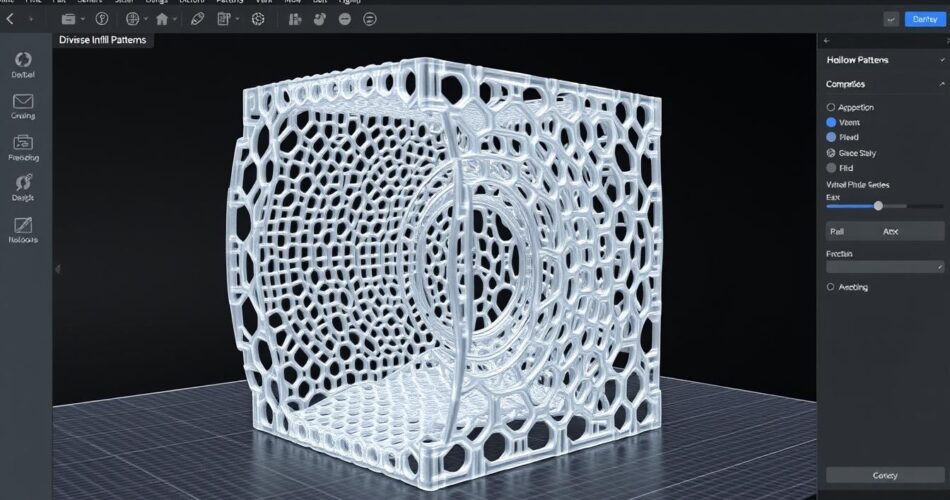

In ChituBox, the infill structure is key for making lightweight 3D prints. It helps keep hollow models strong and stops them from falling apart while printing.

ChituBox has many infill patterns like grid, honeycomb, and triangular. These patterns support your prints inside and make them lighter. This is great for lightweight 3D prints or hollowing models.

ChituBox lets you change the infill density. You can adjust how dense the infill is to make your prints strong yet use less material. This makes your prints both sturdy and cost-effective.

- Try out different infill patterns to find the perfect mix of strength and lightness for your project.

- Change the infill density to improve your print’s quality and stability. Think about your 3D model’s special needs.

- Use ChituBox’s customizable infill settings to fit the internal support to many model types and printing needs.

Learning about infill structure in ChituBox can help you make the most of hollowing models. You can create lightweight 3D prints that look good and are strong. Explore the infill settings to take your 3D printing to the next level.

Drain Hole Placement and Configuration

Drain holes are vital for hollow resin prints. They let uncured resin flow out during printing, avoiding trapped resin. The right placement, size, and number of holes are key when using ChituBox to improve your prints.

Strategic Hole Positioning

Where you put drain holes is crucial for good resin flow without harming your model’s look. ChituBox makes it easy to find the best spots for these holes. You can choose automated or manual settings. This way, your 3D prints look great and drain well.

Size and Number of Drain Holes

The size and number of holes needed vary with your model’s size and detail. ChituBox lets you tweak these settings for your needs. Big models might need more or bigger holes for resin to flow out well. Smaller, simpler designs might just need a few holes.

Preventing Resin Trapping

Drain holes help prevent resin from getting stuck inside your models. They give uncured resin a clear path out. This makes your prints successful and keeps your models strong and durable.

With ChituBox, adding drain holes to your prints is easy. It helps your hollow models drain resin well, leading to better, more consistent prints.

Support Structure Integration with Hollow Models

Working with hollow 3D prints in ChituBox requires support structures for success. These structures keep overhanging parts and delicate areas stable. This prevents them from deforming or failing during printing. ChituBox lets you choose between automatic and manual support generation, fitting your model’s needs.

For the best support structure integration, think about your design’s wall thickness and infill. The right support placement can greatly improve print quality and finish. Adjusting support density, tip size, and contact points helps balance support and product quality.

- Understand the importance of support structures for hollow prints, especially for overhangs and delicate features.

- Explore ChituBox’s automatic and manual support generation tools to customize support placement for your hollow models.

- Adjust support density, tip size, and contact points to optimize print results while ensuring the support structures don’t compromise the surface quality or structural integrity of your hollow print.

- Carefully consider the relationship between support structure, wall thickness, and infill structure to achieve the best possible outcome for your hollow 3D prints.

By effectively integrating support structures with your hollow models in ChituBox, you can improve your 3D printing projects. This ensures optimizing 3d prints with confidence.

Advanced Hollowing Techniques for Complex Models

Working with complex 3D models in ChituBox means hollowing is key. It’s not just about basic hollowing. You’ll need advanced strategies for intricate shapes and successful prints.

Multi-part Model Considerations

Complex models often break into parts for easier printing. Each part might need its own hollowing method. ChituBox lets you create custom hollowing profiles. This way, you can adjust settings for each part based on its details and needs.

Internal Support Strategies

Hollow models can face structural issues, like thin walls or overhangs. ChituBox’s tools help place internal supports. These supports strengthen the hollow parts and prevent print failures.

Weight Distribution Optimization

Hollow models can have uneven weight, affecting print stability. ChituBox’s infill pattern and density controls help balance the weight. By tweaking infill patterns and density, you can make the model more stable.

With ChituBox’s advanced hollowing tools, you can handle complex models confidently. You’ll get high-quality, sturdy, and efficient resin parts.

Optimizing Print Settings for Hollow Models

Creating lightweight 3D prints requires the right print settings. Adjusting settings in ChituBox software is key. This way, you can make high-quality, hollow prints that save time and material.

Exposure time is crucial for hollow models. Longer times help cure thin walls properly. ChituBox has pre-set profiles, but you might need to tweak them for your resin and printer.

Lift speed is also important. Changing it can prevent print failures and make the model more stable during printing.

Layer height affects the print’s quality and time. Thinner layers mean a smoother finish but longer print times. Finding the right balance is key for chitubox settings on hollow models.

| Parameter | Optimization Approach | Impact on Hollow Prints |

|---|---|---|

| Exposure Time | Increase exposure time for thin walls | Ensures proper curing of hollow structures |

| Lift Speed | Adjust lift speed to reduce suction forces | Improves print stability and reduces failures |

| Layer Height | Balance layer height for surface quality and print time | Affects optimizing 3d prints and lightweight 3d prints |

By fine-tuning these chitubox settings, you can enjoy the benefits of lightweight 3d prints. Your hollow models will be strong and look great. Use ChituBox’s features to get the best results for your optimizing 3d prints needs.

Troubleshooting Common Hollowing Issues

Exploring 3D printing with resin can lead to challenges when hollowing models. You might face issues like preventing print failures, managing surface quality, and ensuring structural integrity. Knowing how to tackle these problems is key for successful hollow prints with tools like ChituBox.

Preventing Print Failures

Print failures are a big worry when hollowing models. They can happen if support placement or infill settings are off. Make sure your supports are in the right spots, especially for thin walls or overhangs. Also, tweak your infill settings to improve your prints’ strength.

Surface Quality Management

Getting a smooth surface on hollow prints can be tough. Adjusting wall thickness and drain hole placement helps a lot. Try different wall thicknesses to find the best balance. Also, placing drain holes right can avoid resin trapping and surface defects.

Structural Integrity Solutions

Keeping your hollow models strong is vital, especially if they need to hold weight. Use ChituBox to fine-tune infill patterns and density. This will boost your prints’ strength and stability.

Fixing common hollowing issues takes time and patience. Try different settings, see what works, and keep improving. With practice, you’ll get the results you want for your hollow prints.

Conclusion

ChituBox offers great tools for making and improving hollow 3D prints. It’s key to know about infill structures and hollowing methods for good resin printing. By learning the right settings and tips for wall thickness, drain hole placement, and support, you can make prints that are both light and strong.

ChituBox’s advanced features help users handle complex models. It uses strategies like multi-part design and internal support to improve print stability. The software also helps solve common problems, making the printing process smoother and more efficient.

In the end, ChituBox’s hollowing features can greatly enhance your 3D printing work. Whether you’re new or experienced, using ChituBox can take your 3D printing to the next level. It’s all about optimizing 3D prints and hollowing models.