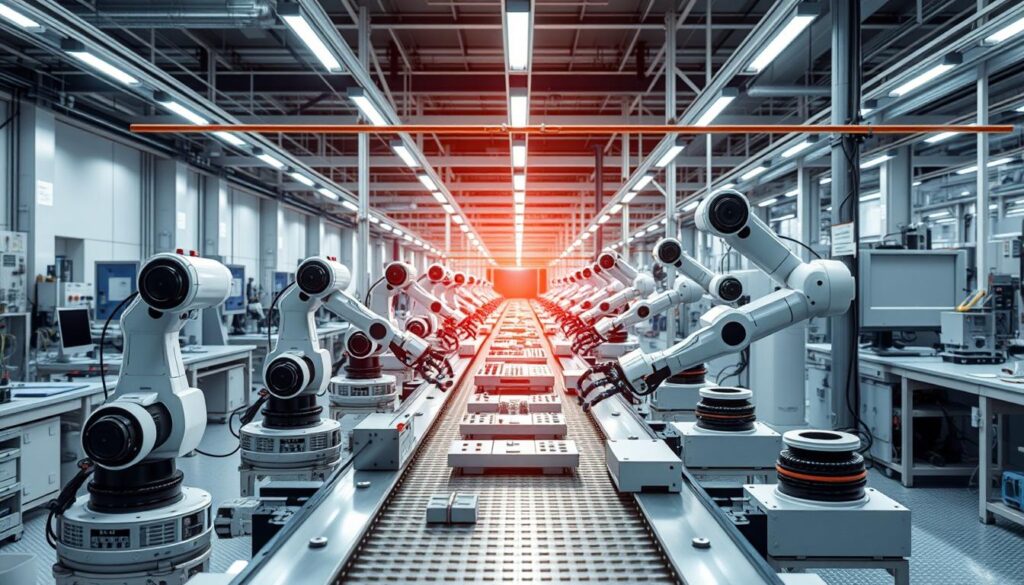

Technology is changing the world fast, especially with automation and robotics. These technologies make things more efficient, precise, and safe. They are changing how we work, live, and interact with our surroundings. From factories to hospitals, the possibilities are vast.

Robotics and automation work together closely. Robotics is about designing and using programmable machines. Automation is about using technology to do tasks with little human help. Together, they are changing industries, making things more productive, and pushing what’s possible.

This guide will cover the basics of modern robotics and automation. We’ll look at the key parts of robotic systems and how automation is changing our lives. We’ll see how robots, from industrial to collaborative, are making a big impact. Let’s explore the exciting world of automation and robotics together.

Understanding the Fundamentals of Automation and Robotics

Automation and robotics are changing the world, making industries more efficient. They are key in improving how we make things and work. At the heart of these changes are the basics of modern robotics and smart tech in automation.

Basic Principles of Modern Robotics

Modern robotics is about making machines that can see, decide, and act. They use sensors, control systems, and smart algorithms. This lets robots work with precision and keep tasks consistent.

Core Components of Automation Systems

- Control systems: Manage the parts of an automation system.

- Sensors: Give feedback on the system’s state, helping with adjustments.

- Actuators: Turn electrical signals into movement, letting systems act.

- Communication interfaces: Help parts talk to each other smoothly.

Integration of Smart Technologies

Adding smart tech like artificial intelligence (AI), machine learning, and advanced sensors boosts robots’ abilities. These tools make robots more independent, flexible, and smart. They help in many fields, from making things to helping in healthcare.

| Technology | Application | Benefits |

|---|---|---|

| Artificial Intelligence | Predictive maintenance, process optimization, autonomous decision-making | Increased efficiency, reduced downtime, enhanced adaptability |

| Machine Learning | Quality control, anomaly detection, system optimization | Improved product quality, reduced errors, continuous improvement |

| Advanced Sensors | Improved sensing, data collection, and monitoring capabilities | Enhanced system monitoring, real-time adjustments, and increased reliability |

Learning about what is automation and robotics helps us see their big impact. Knowing the basics of robotics automation and smart tech shows us how they change industries. It’s exciting to see how modern robotics principles are making a difference.

Essential Components of Robotic Systems

Robotic systems are key to modern industrial automation. They use many components to make automation and robotics work better. At the heart of these systems are the robotic system components. They work together to boost productivity, efficiency, and safety in factories.

The main parts of robotic systems include:

- Control systems, like programmable logic controllers (PLCs), that control machines in real-time

- Motors, including DC, servo, and stepper motors, that move and actuate robotic arms and end-effectors

- Actuators that turn energy into motion, letting robots do many tasks

- Sensors, such as infrared, ultrasonic, and LiDAR, that help the robot know its surroundings and position

- End-effectors, the tools or grippers at the end of a robotic arm, for specific tasks

- Power supplies and generators that give the needed electrical power to the industrial automation robotics system

- Communication systems, including Wi-Fi and Bluetooth, that let robots work with other machines and humans

- Versatile operating systems and programming languages that help develop and use robotic applications

These parts work together to let robots do tasks on their own or with some help. They can interact with their environment and change as needed. The use of these advanced parts in systems like autonomous guided vehicles (AGVs) and autonomous mobile robots (AMRs) makes industrial processes better. This boosts competitiveness and prepares for the future.

| Component | Description |

|---|---|

| Control Systems | Programmable logic controllers (PLCs) that ensure reliable real-time control of machinery |

| Motors | DC, servo, and stepper motors that power the movement and actuation of robotic arms and end-effectors |

| Actuators | Convert energy into motion, enabling robots to perform a wide range of tasks |

| Sensors | Infrared, ultrasonic, and LiDAR sensors that provide the robot with awareness of its surroundings and position |

| End-Effectors | Tools or grippers at the end of a robotic arm, designed for specific tasks and applications |

| Power Supplies | Electrical power units, generators, and uninterruptible power supplies (UPS) that deliver the necessary power |

| Communication Systems | Wi-Fi and Bluetooth that enable robots to coordinate with other machines and human operators |

| Operating Systems and Programming | Versatile operating systems and programming languages that provide a stable foundation for robotic applications |

The smooth working together of these robotic system components is key for industrial automation robotics. It makes automation better and boosts productivity, efficiency, and safety in factories.

Types of Industrial Robots and Their Applications

The world of industrial robotics is full of different machines for various tasks. From the flexible collaborative robots (cobots) that work with humans to the strong articulated robots and precise Cartesian systems, each robot has its own strengths. They all bring unique abilities to the manufacturing world.

Collaborative Robots (Cobots)

Cobots are changing the game in manufacturing. They are made to work with humans, making work safer and more efficient. These robots have special sensors and control systems. They can tell when people are nearby and adjust their actions to avoid accidents.

Articulated Robots

Articulated robots can move in many ways, thanks to six or more axes. They are great for tasks that need flexibility and skill. Used in assembly, welding, painting, and more, they can get into tight spaces and do many things.

Cartesian Robots

Cartesian robots, or gantry robots, move in a straight line along the X, Y, and Z axes. They are precise, strong, and affordable. This makes them perfect for tasks like moving materials, tending machines, and picking up items.

| Robot Type | Key Features | Common Applications |

|---|---|---|

| Collaborative Robots (Cobots) |

|

|

| Articulated Robots |

|

|

| Cartesian Robots |

|

|

Each industrial robot has its own special abilities and uses. Manufacturers pick the best one for their needs. As the industry grows, these robots are key to making work more efficient, productive, and innovative in manufacturing.

Manufacturing Automation Solutions

In today’s fast-changing world of manufacturing, automation is changing how we make things. It ranges from fixed automation for making lots of the same thing to flexible automation for making different things. These new technologies include robots, automated assembly lines, and more, making industries like cars, planes, food, and medicine work better.

Automation helps make things faster, better, and cheaper. Fixed automation is great for making lots of the same thing because it costs a lot upfront but makes lots of things quickly. Programmable automation is better for making smaller batches because it’s cheaper and faster to change what you’re making.

Flexible automation is even better because it changes what it’s making quickly. This means it doesn’t waste time when you need to make something different. These systems use special computers to control everything and make sure things happen in the right order.

| Automation Type | Production Characteristics |

|---|---|

| Fixed Automation | High initial investment, high production rates, suitable for large volumes |

| Programmable Automation | Suitable for batch production, lower production rates due to reprogramming |

| Flexible Automation | Minimizes lost production time through quick equipment changeover |

As manufacturing keeps changing, automation is more important than ever. By using these new technologies, companies can make more, better, and cheaper things. This helps them succeed in today’s fast and competitive world.

The Role of Artificial Intelligence in Modern Robotics

Artificial intelligence (AI) has changed robotics a lot. Now, robots can work on their own, adapt to new situations, and do things more efficiently. AI helps robots learn, see, and predict problems, starting a new chapter in robotics.

Machine Learning Applications

AI is making robots smarter with machine learning (ML) algorithms. These algorithms let robots get better with practice, not just by following rules. Machine learning robotics helps robots adjust to new situations, choose the best actions, and make smart decisions. This makes them more productive and efficient.

Computer Vision Systems

Computer vision robotics is key in AI robots. These systems let robots understand pictures and videos and act on them. They can move around, pick up things, and even understand human gestures and faces. This makes working with robots easier and more natural.

Predictive Maintenance

AI is also changing how robots are maintained. It looks at sensor data and past performance to forecast when something might break. This way, robots can be fixed before they fail, saving time and money. It makes robots last longer and work better.

As AI and robotics work together more, we’ll see even more new things. AI will help make factories safer, medical care better, and farming more sustainable. AI’s role in robotics is changing the game and is crucial for the future of automation.

Industrial Applications and Use Cases

Industrial automation robotics and robotics have many uses across different fields. These include manufacturing, healthcare, agriculture, transportation, and retail/e-commerce. In manufacturing, robots are great at tasks like assembly, welding, and checking quality. They work faster and more accurately than humans.

In healthcare, robots help doctors with complex surgeries and aid in patient recovery. In farming, robots help with planting, harvesting, and watching over crops. This makes farming more efficient and cuts down on the need for manual labor.

Autonomous vehicles and drones are changing how we move goods and people. They make transportation safer and more efficient. In retail, robots help manage stock and fill orders, making shopping better for everyone.

| Sector | Industrial Robotics Applications |

|---|---|

| Manufacturing | Assembly, Welding, Quality Control |

| Healthcare | Surgical Robots, Rehabilitation Systems |

| Agriculture | Planting, Harvesting, Crop Monitoring |

| Transportation | Autonomous Vehicles, Drones |

| Retail/E-commerce | Inventory Management, Order Fulfillment |

The wide range of industrial automation robotics and robotics applications shows how these technologies are changing many industries. As we need more productivity, efficiency, and safety, robots will play an even bigger role. They will help shape the future of work in many areas.

Benefits of Implementing Robotic Automation

Adding robotic automation to your business can bring many benefits. It automates repetitive tasks and uses modern robotics’ precision and speed. This can change how you work and help your company grow.

Increased Productivity and Efficiency

Robotic systems work all the time, without breaks. They do tasks fast and accurately. This means your business can do more in less time, with studies showing a 100% productivity boost.

Cost Reduction and ROI

Robotic automation can save your business a lot of money. It can cut costs by 25-50% and offer a big return on investment. This leads to higher profits and a stronger financial position.

Enhanced Workplace Safety

Robots make workplaces safer for people. They handle risky tasks, like heavy machinery or toxic materials. This lowers the chance of accidents and injuries, saving money on worker’s compensation and insurance.

Using robotic automation can make your business more productive, save money, and keep workers safe. It’s a smart move that can help your company grow and succeed.

| Benefit | Impact |

|---|---|

| Increased Productivity | Up to 100% productivity boost |

| Cost Reduction | 25-50% reduction in operational costs |

| Improved Safety | Reduced workplace accidents and injuries |

Current Trends in Automation Technology

The world of automation technology is changing fast. New trends are shaping the future of making things and more. We see smarter systems that can handle complex tasks and adapt to changing needs.

Advanced sensors are becoming key. They help us see and control what’s happening in production. These sensors check on machines, how much we’re making, and what we have in stock, all in real-time.

Artificial intelligence (AI) and machine learning are playing a bigger role. AI can spot when machines might break down by watching how they move and how hot they get. This lets us fix things before they break down. Machine learning helps AI get better at predicting these problems, making things run smoother.

| Automation Technology Trends | Key Advancements |

|---|---|

| Sensor Integration | Real-time monitoring of machinery conditions, productivity, and inventory levels |

| AI and Machine Learning | Predictive maintenance, equipment failure prevention, and continuous process improvement |

| Increased Autonomy | Collaborative robots (cobots) and mobile manipulators (MoMas) automate complex tasks |

| Workflow Integration | Industrial Internet of Things (IIoT) and cloud computing enable seamless data exchange and collaboration |

| Real-time Responsiveness | Edge computing and digital twins optimize production and decision-making |

Collaborative robots (cobots) and mobile manipulators (MoMas) are changing things for small and medium-sized businesses. They can work with people, doing hard tasks and making things better without needing a lot of setup.

The mix of Industrial Internet of Things (IIoT) and cloud computing is making it easier to share data and work together. This helps us make decisions fast and improve how we make things.

As these trends keep moving forward, businesses will see better productivity, lower costs, and safer workplaces. By using these new tools, companies can stay on top and keep up with the fast pace of making things.

Challenges and Considerations in Implementation

Starting automation and robotics in businesses comes with big challenges. You need to think about how to integrate them, the costs, and training. These are key to making the most of these new technologies.

Integration Complexities

Making robotics and automation work with what you already have is hard. You have to make sure everything fits together right. You also need to plan for updates and tech support. Getting these right is key to a smooth start.

Cost Analysis and Planning

The money side of automation is important. You need to look at the costs and see if they’re worth it. Planning well helps make sure you get a good return on your investment.

Training Requirements

For robotics and automation to work, your team needs to know how to use them. Training your staff is a big part of getting started. Working with schools can also help find the right people for the job.

By tackling these issues head-on, businesses can make automation and robotics work well. This unlocks their full power and helps businesses grow.

Conclusion

The future of automation and robotics is changing the industrial world. New technologies like artificial intelligence and collaborative robots are making big impacts. Companies that use these technologies will be more productive, save money, and keep their workplaces safe.

By 2023, there will be about 4.1 million industrial robots worldwide. This shows how much the industry wants to automate. “Smart factories” powered by AI are changing how we make things. Up to 40% of jobs could be automated in the next 15 years, changing the job market.

It’s important to keep up with the latest in industrial automation. Knowing about new trends and technologies can help your business succeed. Embracing automation and robotics can make your business more efficient, safe, and competitive.